Cardboard Chair

Written 8-29-19

As the culmination of everything we learned during the school year, our final project for IB Design Tech was to build a cardboard chair. The design process was very similar to the salad tongs, so I won’t go over it in too much detail. We took multiple measurements of every student in class to determine the 95th and 5th percentile bounds to create specifications for our chair. Using these measurements, we determined height and depth requirements to ensure our chair would have good ergonomics across most users.

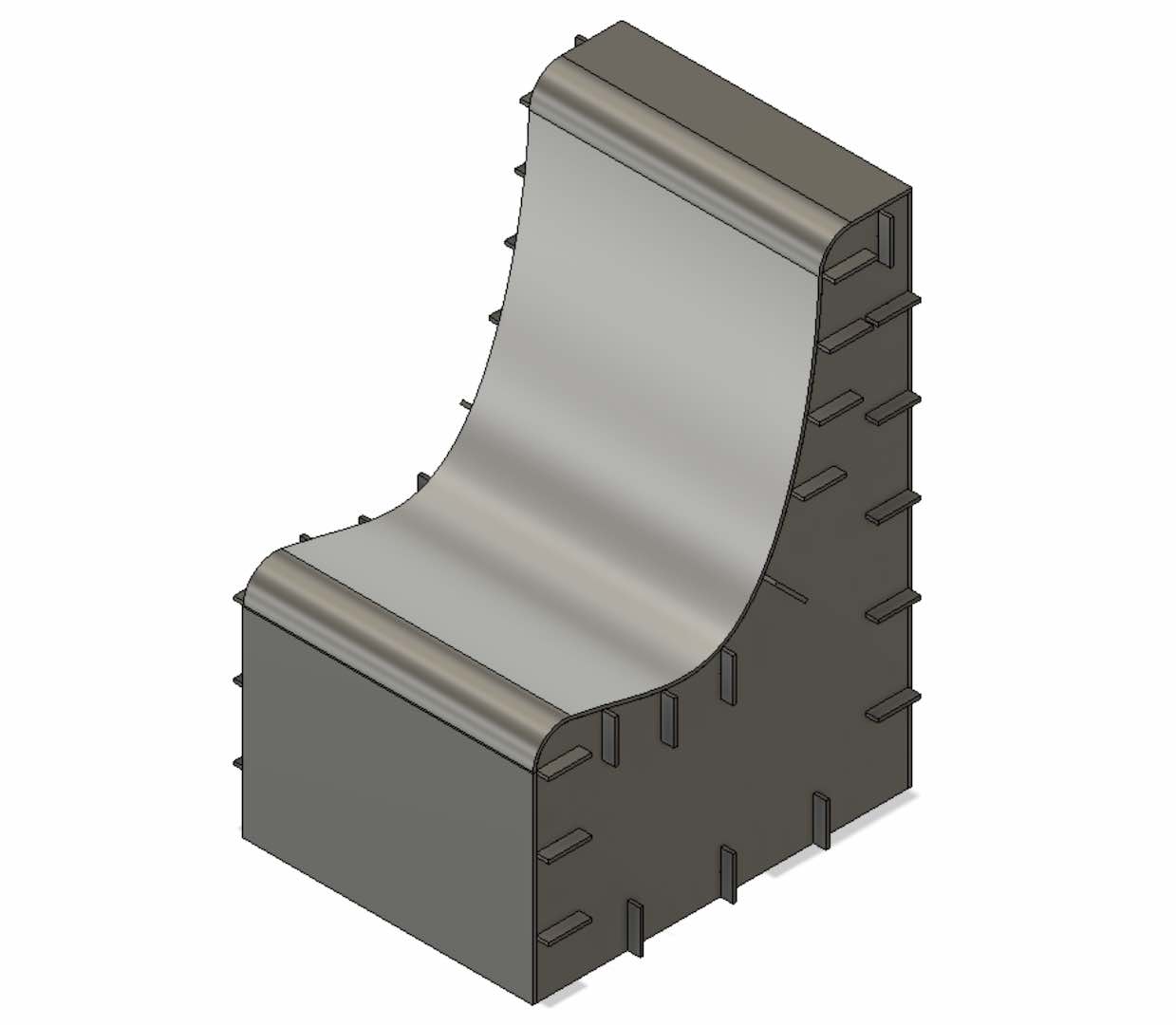

CAD

After going through the design process to get design specifications, we started modeling our chairs. Although using SolidWorks would’ve been just as easy, I ended up using Fusion 360. My main focus was ergonomics, so I used a spline curve to design the seat area in an attempt to better fit the curves of the human body. This did make it harder to manufacture because I had to approximate the curve instead of plotting straight lines, but it worked out in the end.

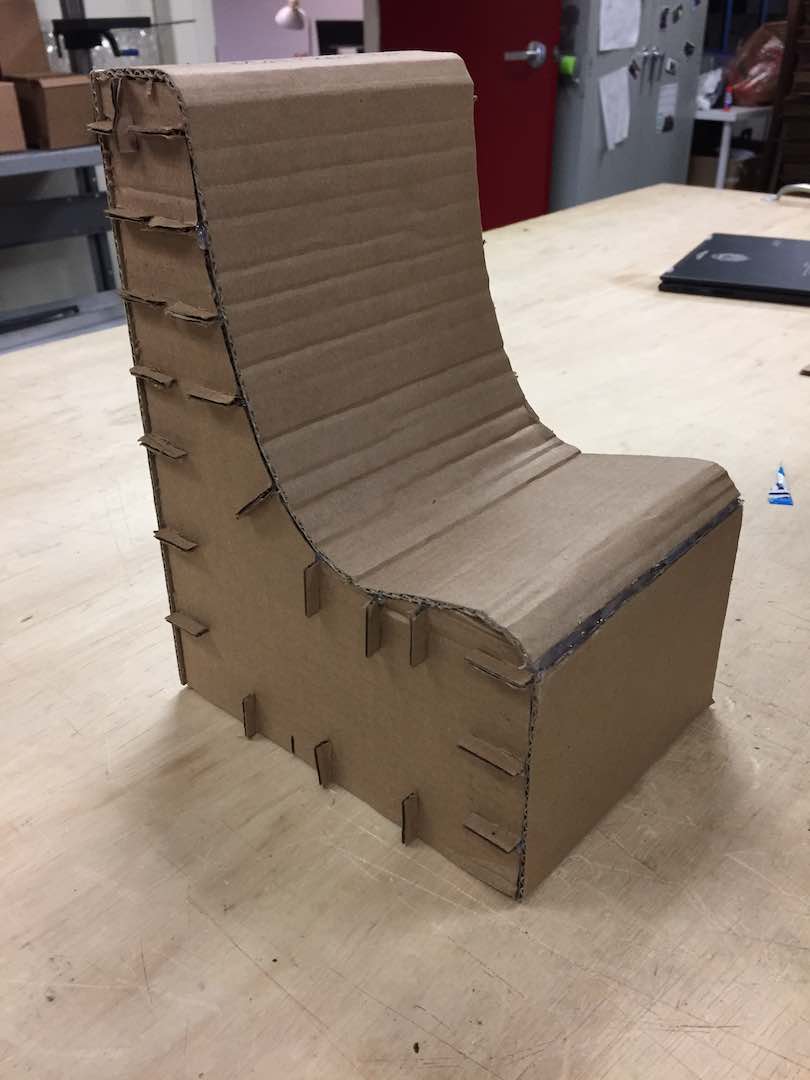

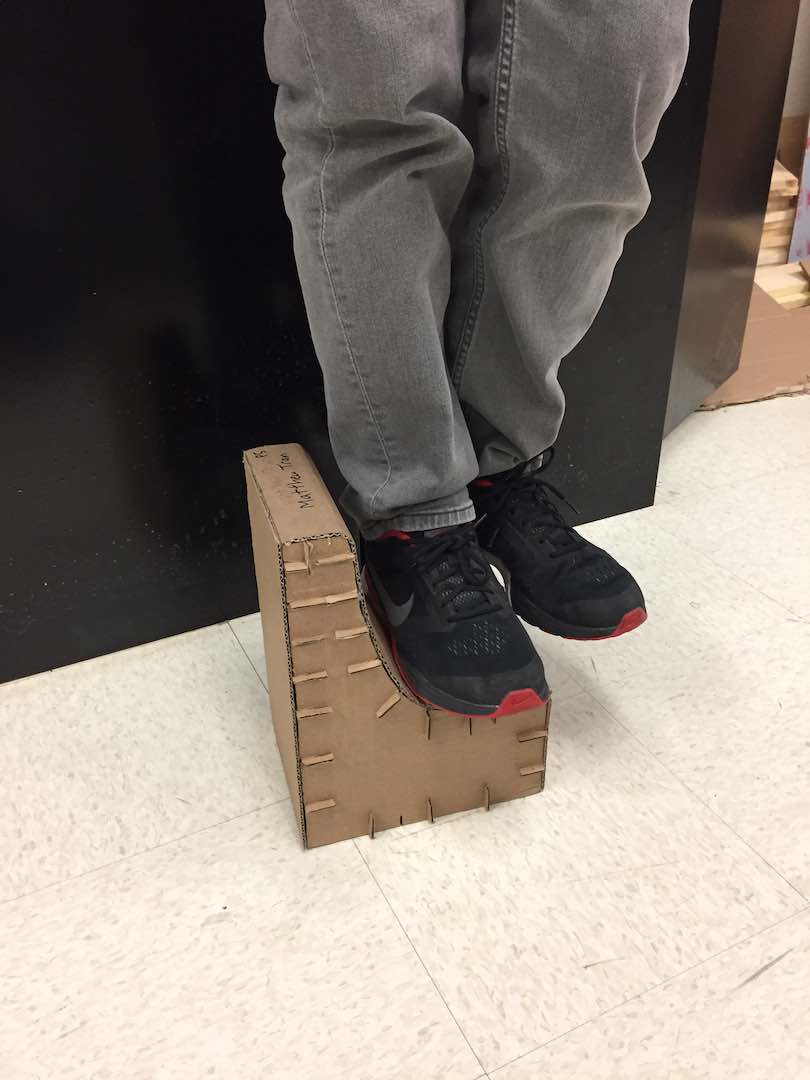

Mini Prototype

Before making a full size model, we had to make a 1:3 scale version. Like with the salad tongs, we had to thoroughly test the prototype to ensure it fulfilled all specifications. This included standing on it. Here’s some pics:

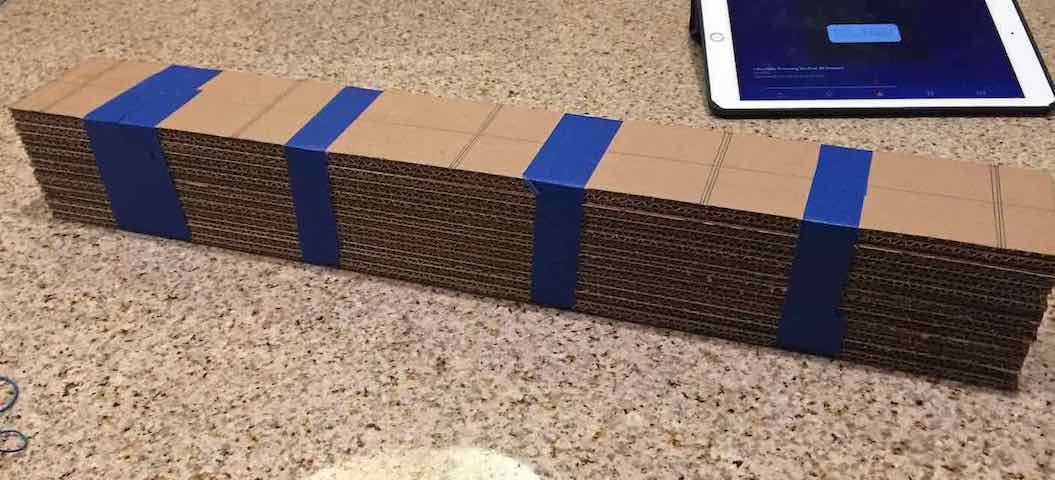

Final Product

After our prototype was finished and most specifications met, we built the final, full-scale chair. The build process was pretty much the same as the scale model, but bigger.

Like with the salad tongs, we also had to do a bunch of testing to make sure our chair met all specifications. Today, the chair has been recycled because I tossed it after intentionally breaking it with multiple jumps onto the seat.

Comments