Arc Lighter v1

Written 8-21-19

Thinking back to my younger years, it appears that I always had a fascination with high voltage. Because of the incredibly high voltages they could generate, things like stun guns, plasma globes, and Tesla coils were absolutely awe-inspiring. Finding out about arc lighters was equally cool because they could generate around 10kV in the palm of your hand. Of course, that meant I had to figure out how to build one. Either from not wanting to wind my own transformer or always having other stuff to do, I never really got around to it.

Reverse Engineering an Existing Design

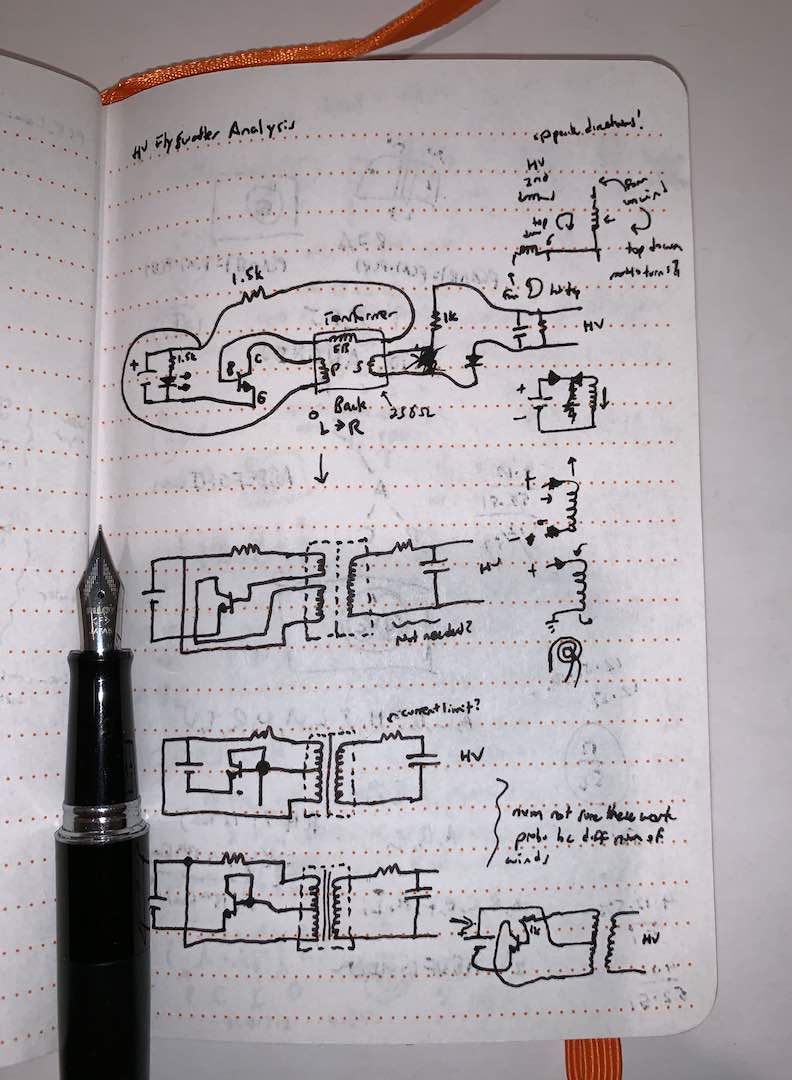

Coming back for the summer after my first year at Berkeley I randomly decided, “Hey! Let’s take a look at that arc lighter again.” I had bought an electric flyswatter from Harbor Freight not too long ago so I decided to take a look at it. Taking a look at the circuit (after discharging the capacitor of course), I saw that the high voltage side capacitor was rated at 600v, so I assumed the output voltage was less than that. Hooking up my trusty Craftsman multimeter that had served me for almost a decade, I heard a pop and saw that my multimeter had broken. After a brief grieving period, I wisely decided not to hook up my expensive Fluke 117 but instead a cheap multimeter I got for free at school. That one broke too. I had a pretty powerful circuit on my hands, so I decided to reverse engineer it.

After analyzing the circuit and redrawing it, it became pretty clear how it worked. When the circuit is turned on, current flows through the feedback coil and through the base of the BJT transistor, turning on the primary coil. The magnetic field generated by the primary induces a reverse voltage in the feedback coil, turning off the BJT and thus the primary. The primary coil’s magnetic field collapses, and the induced voltage in the feedback coil drops. The BJT turns on again, and the cycle continues. This cycle of on and off in the primary coil generates the AC signal necessary to induce a higher voltage in the secondary.

Building My Own Circuit

Doing some research, it seems like most people use some variation of this circuit for their arc lighters. To get the turns ratio necessary to produce a good arc, they usually took an existing one and rewound the primary with fewer turns.

That’s when I ran into my first problem. Arcs formed between the secondary’s coil windings when the voltage was high enough, effectively destroying the transformer. I did attempt repairs by soldering wires to the super thin magnet wire, but this fix proved only temporary. I tried using a CFL inverter transformer instead, which could handle higher voltages. It worked, but I still broke two of them before finalizing a working design.

Another issue I ran into was heat. If the arc was on longer than a couple seconds, the transistor would get too hot. Using MOSFETs produced satisfactory arcs but far more heat than BJTs. I searched for an improved circuit and found GreatScott’s which worked really well. The waveform at the primary was now a sine wave instead of the jagged one of the old circuit. I could even keep an arc going for about a minute before the MOSFETs got too hot.

Putting It All Together

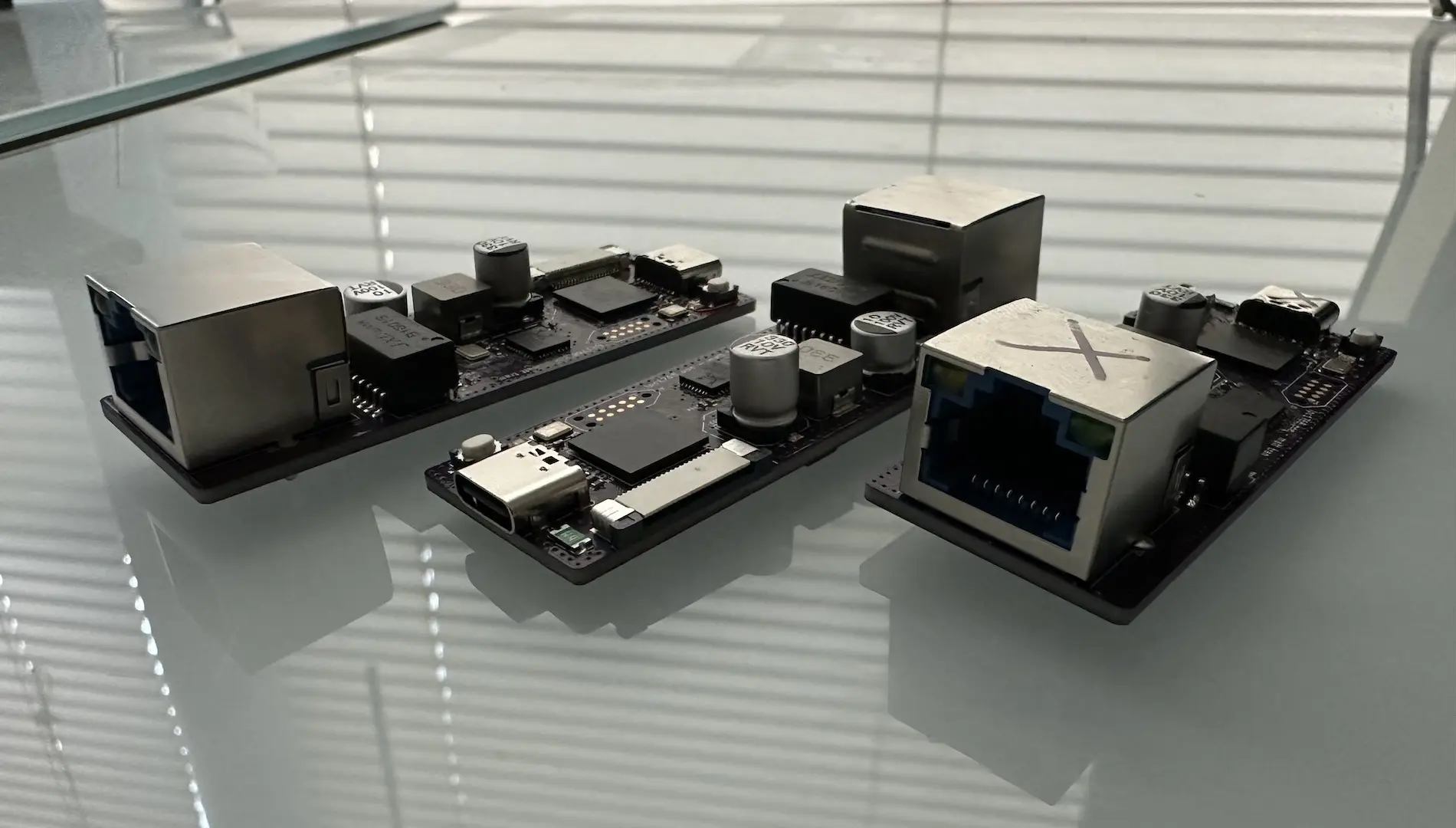

With the circuit finalized, I was ready to put everything into a nice case.

I initially intended to make this lighter a USB charger too because of the 18650 Li-ion battery I was using, but for some reason, the high current draw from the lighter causes the HT4928S to heat up and release the magic smoke. So for future reference, don’t use it for anything that’s powered directly off the battery.

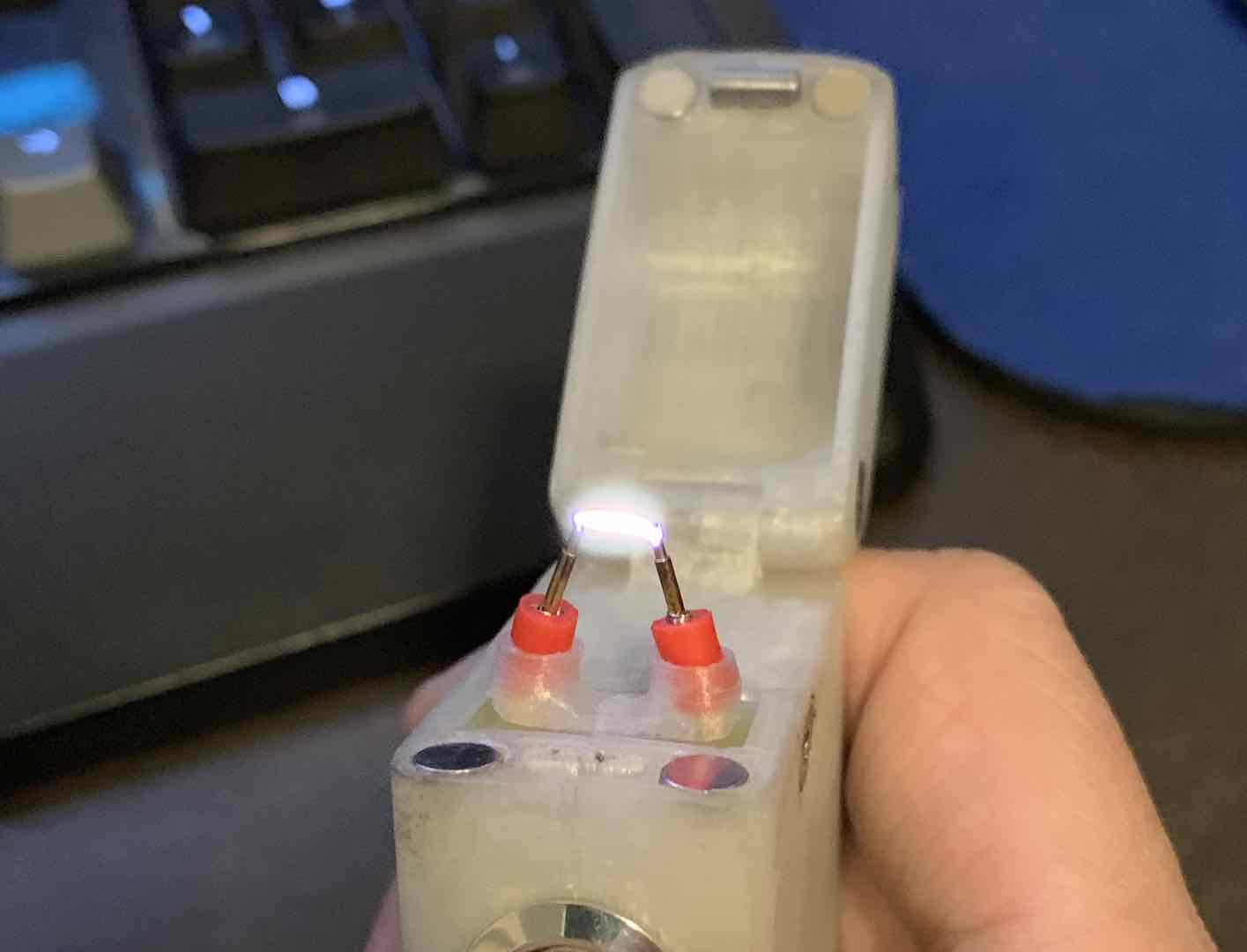

After a bunch of sanding and gluing in some magnets, I had a pretty cool lighter on my hands. It’s easily taken apart for debugging/maintenance, has an elegant on switch, and a lid with a nice tactile feel. The one thing I still needed to finalize was the electrode material.

Picking an Electrode

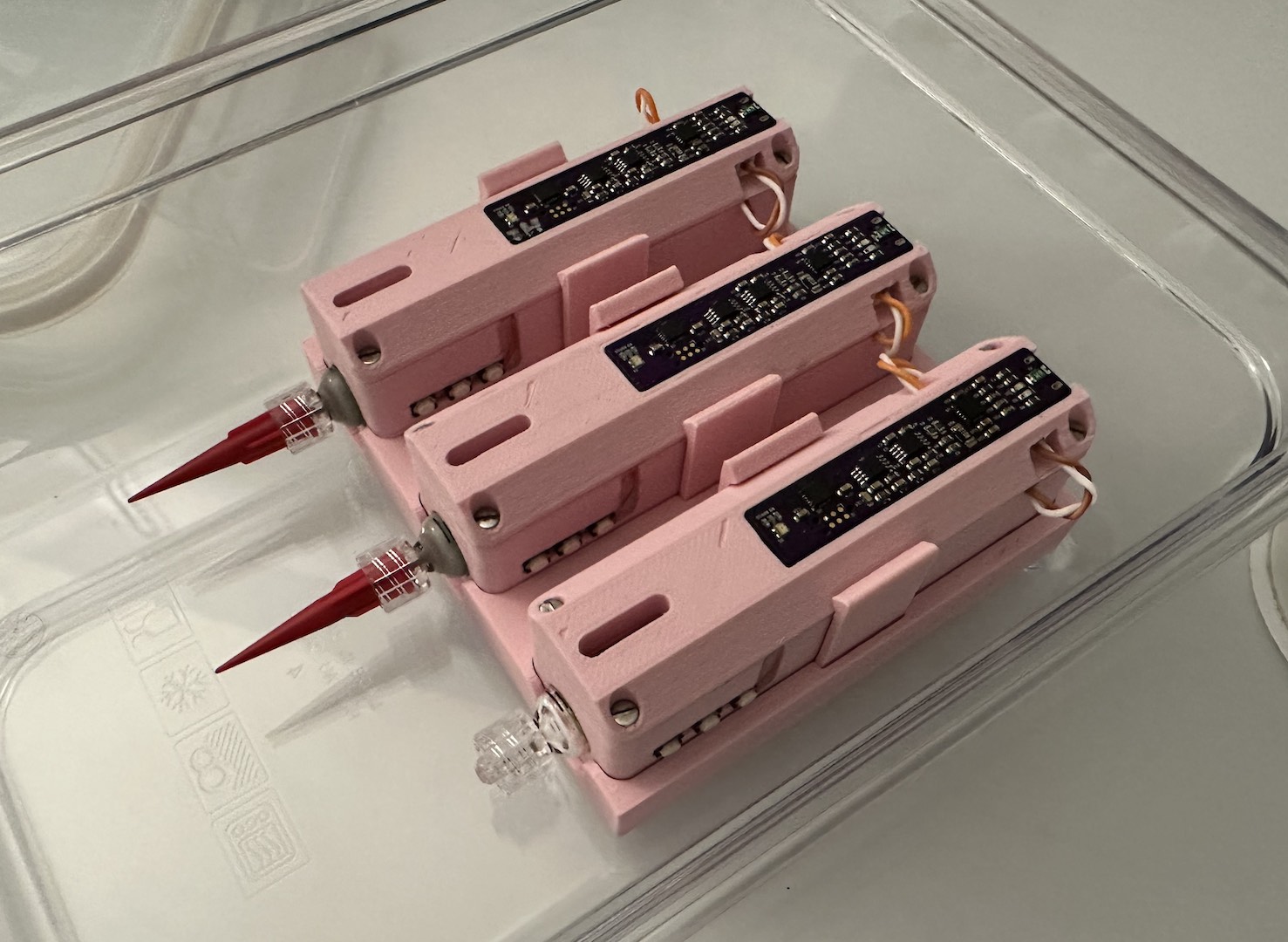

The issue with using an arc is that it’s basically plasma which is quite hot. The tips of the electrodes tend to oxidize over time, making it more difficult to start an arc. They also heat up the electrodes entirely over time which is why I used a fiberglass insert and silicone tubing around the wires.

At first I tried using these Pogo pins I got off eBay because they were probably oxidation resistant. They worked for awhile, but the nice orange arc they created was a telltale sign they wouldn’t last.

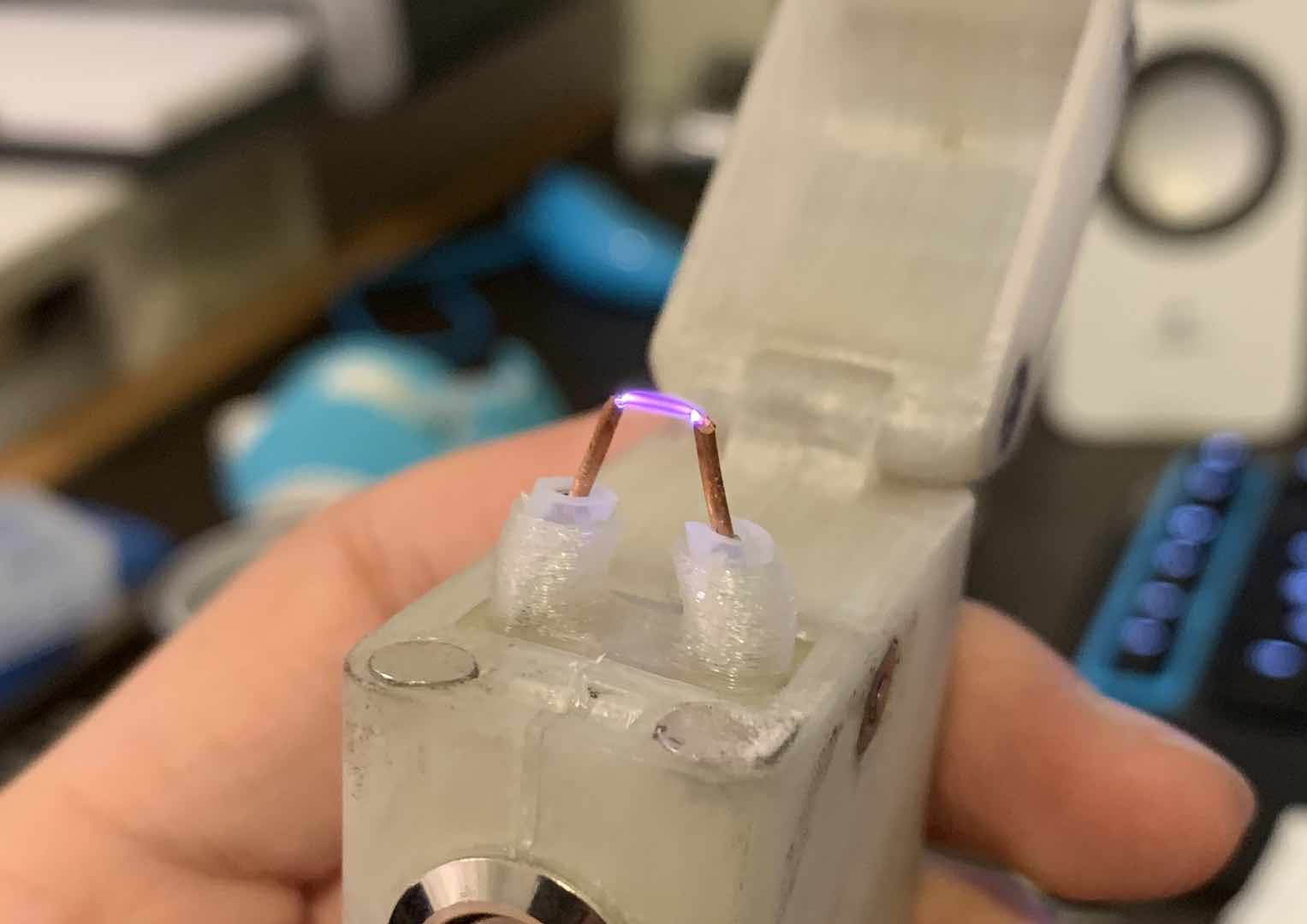

Next I tried using copper electrodes because GreatScott used them in his arc lighter. It worked really well for quite awhile but they oxidized and failed to create a reliable arc. It seems that whatever circuit I cooked up was more powerful than I thought. (The largest electrode spacing I could reliably use was around 6-7mm which is about 20kV.)

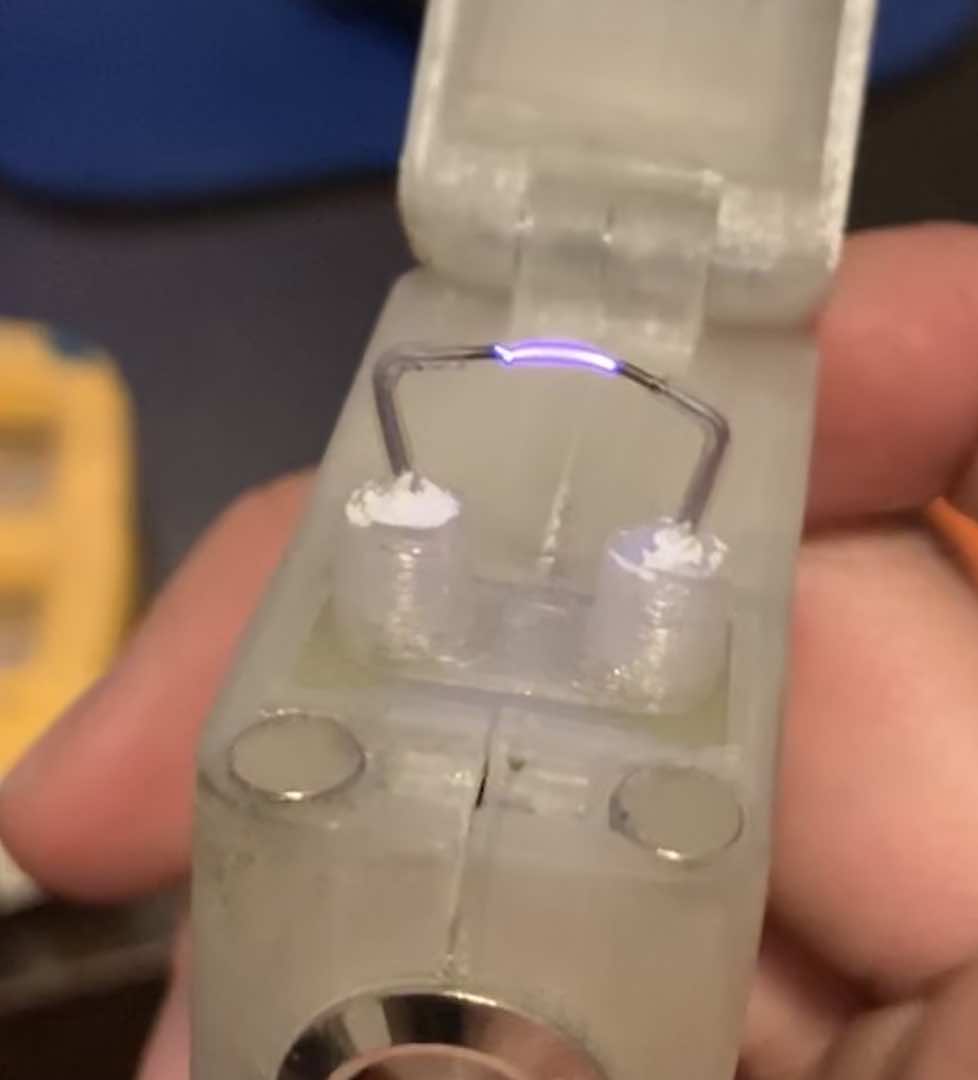

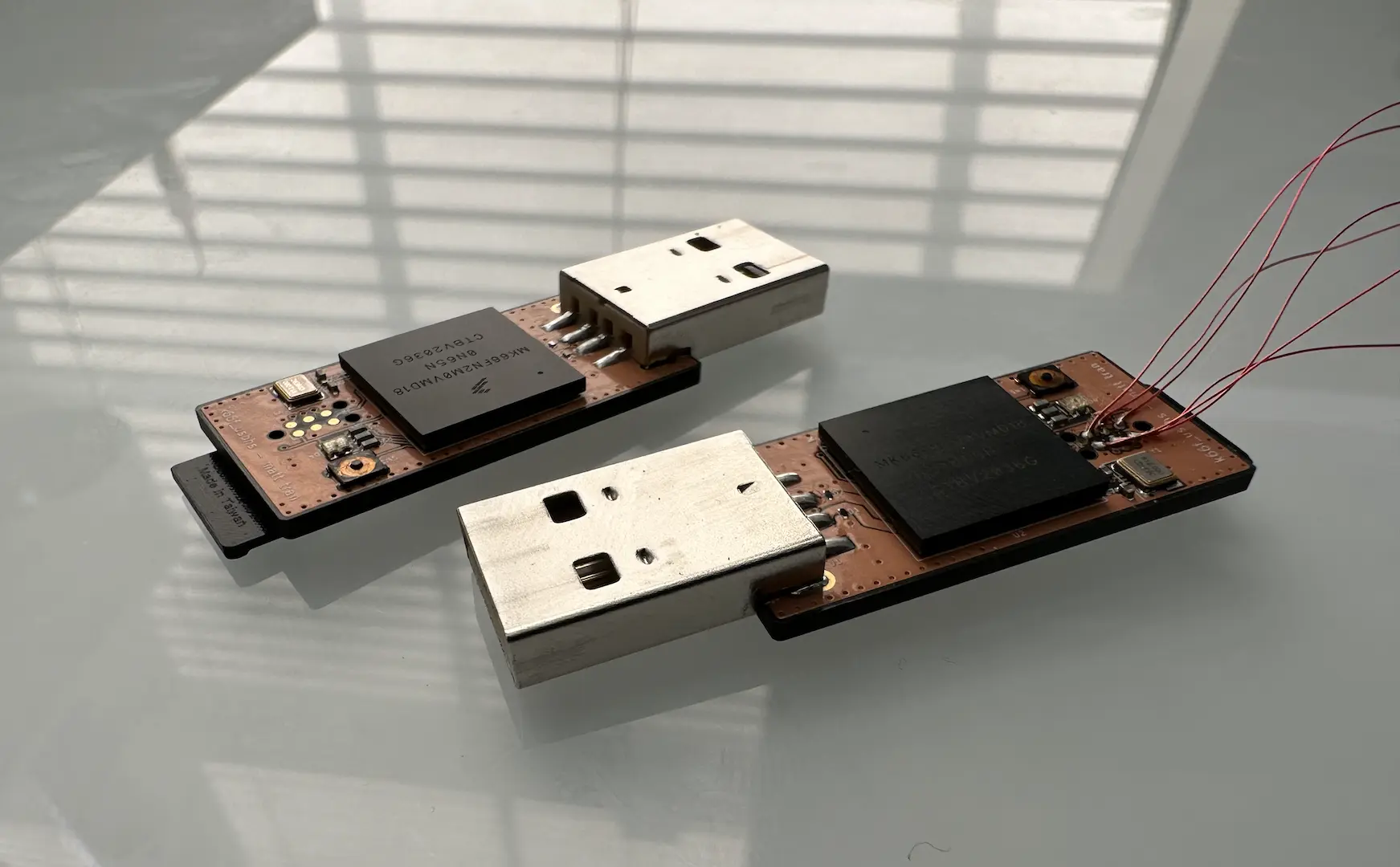

The last thing I tried were these tin plated copper wires I got from an arc lighter kit I bought for reference. Looking at commercial arc lighter teardowns, I noticed that they used the same wires but also used a ceramic casing around them. I don’t have the ability to acquire or machine ceramic yet so I stuck to just using the wire. Thankfully, it’s still working to this day.

Comments