Salad Tongs

Written 8-29-19

One of the projects we had to do in IB Design Tech was designing salad tongs. It was a course not only about CAD using SolidWorks, but also the entire design process. Not only was this class super fun and educational, it also formalized the process of designing products. Being mostly self-taught, it’s really nice having a name for a lot of things I do automatically and being shown a couple of details that I never would’ve learned on my own.

Surprisingly, I don’t have any of the documentation we made for this project. It was probably all on the Google Drive which was deleted after I left high school. Instead, I’ll just give a brief overview of the entire design process to the best of my memory’s abilities.

Design Process

First, we defined our problem, salad tongs. Then we did a bunch of research to come up with design requirements, a list of general ideas that our product had to eventually fulfill. In addition, we took hand measurements of every student in class as well as family members. We also took a look at past designs to help with the design requirements as well as the next stage: brainstorming. During brainstorming, we came up with different approaches and designs to solve the problem. Afterwards, we made design specifications which had a lot more detail than the design requirements, including material choice, manufacturability, etc.

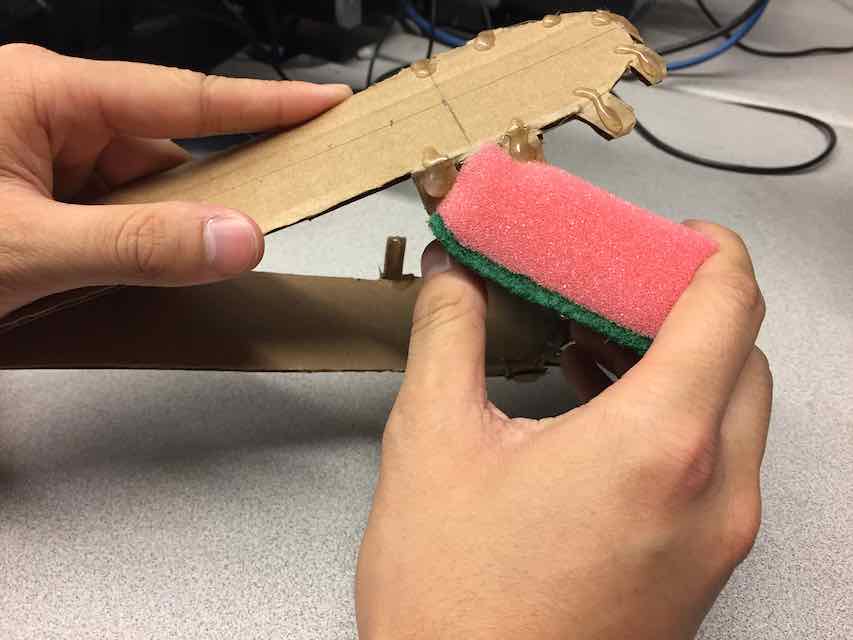

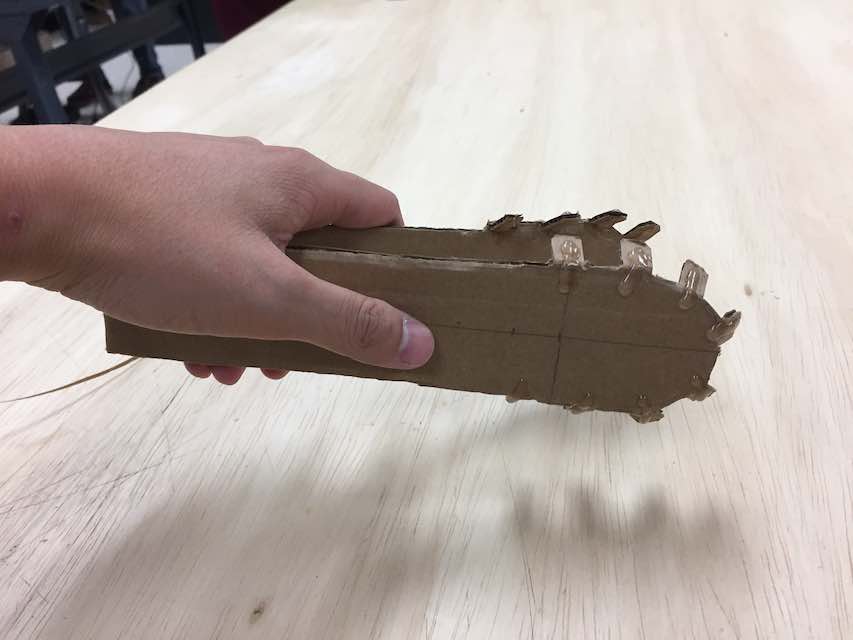

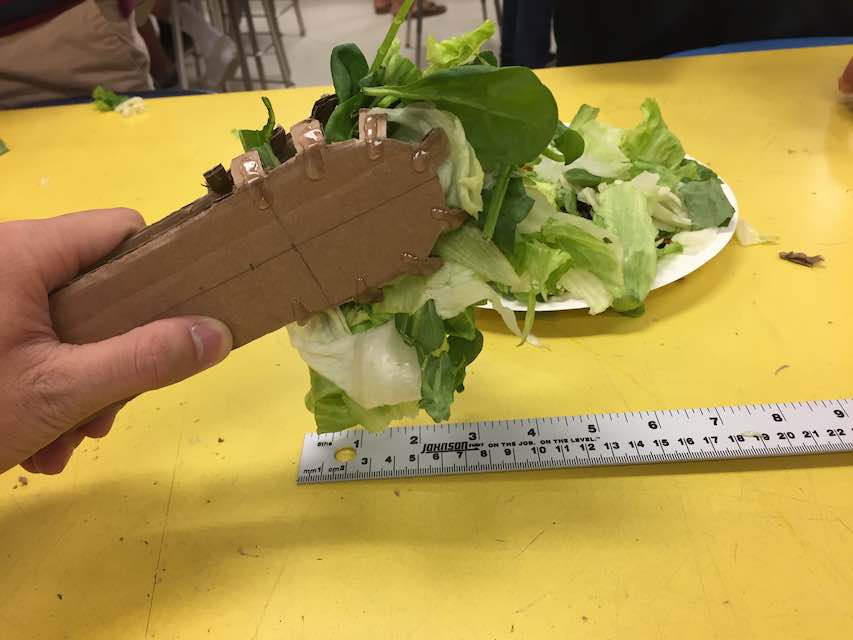

With the design specifications finished, we moved on to cardboard prototypes. We used these prototypes to demonstrate the fulfillment of pretty every specification that wasn’t final material specific. Here’s some pictures of the cardboard prototypes:

Final Design

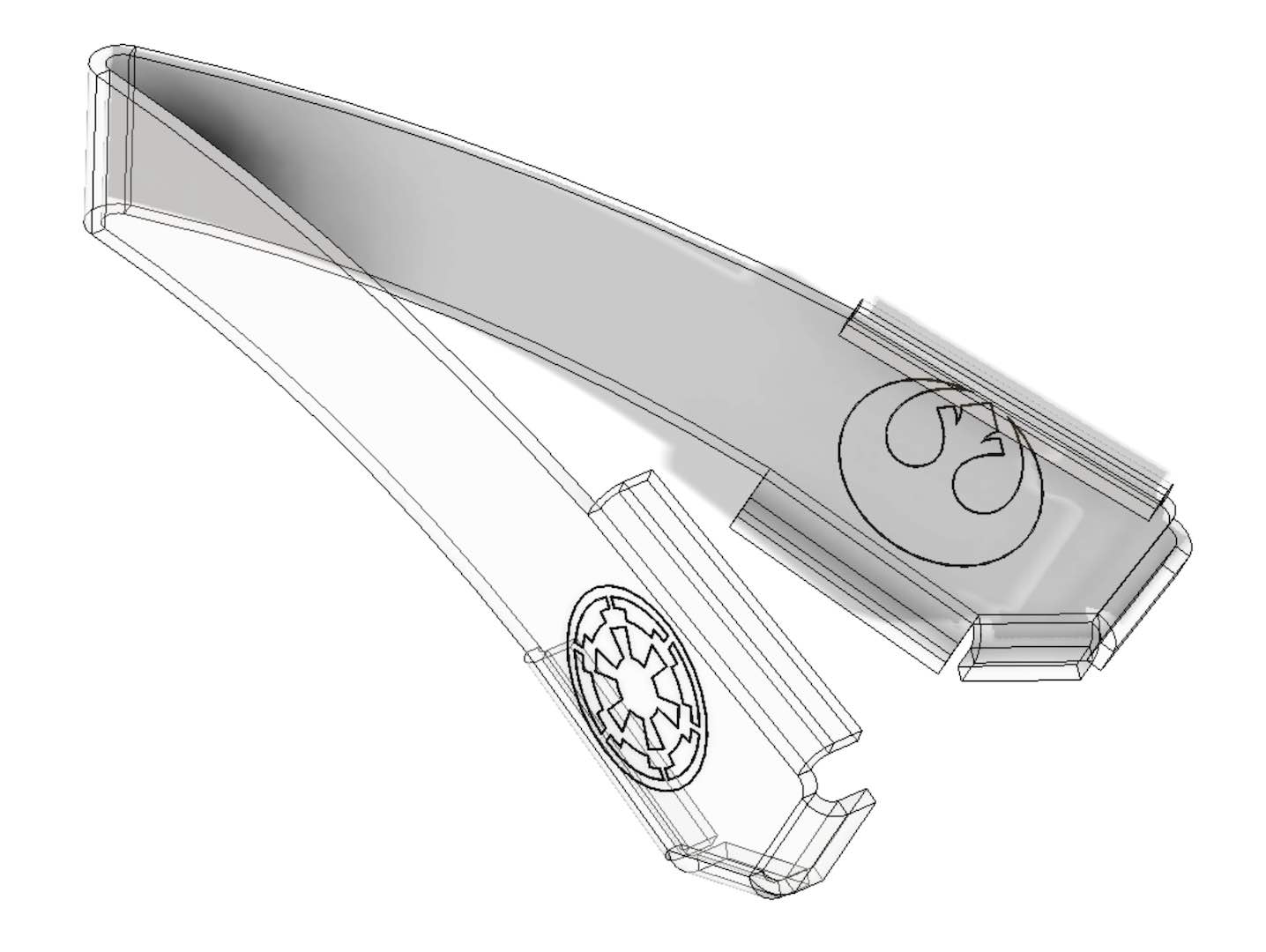

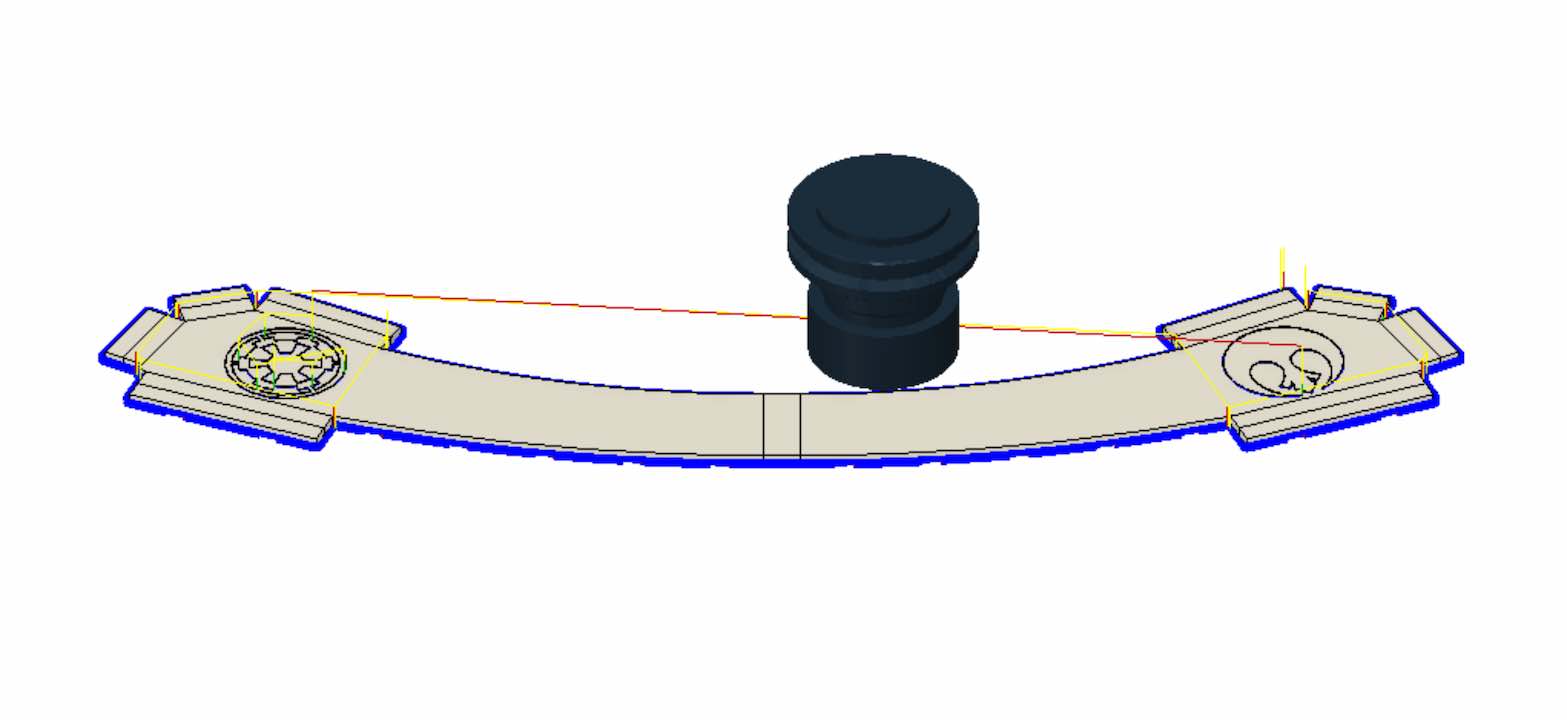

After we were satisfied with out cardboard prototypes, we moved to SolidWorks to finalize our design for manufacturing with acrylic. I actually used Fusion 360’s sheet metal mode to design the salad tongs then moved them into SolidWorks. I could’ve done it in SolidWorks, but we didn’t have time to learn sheet metal mode formally.

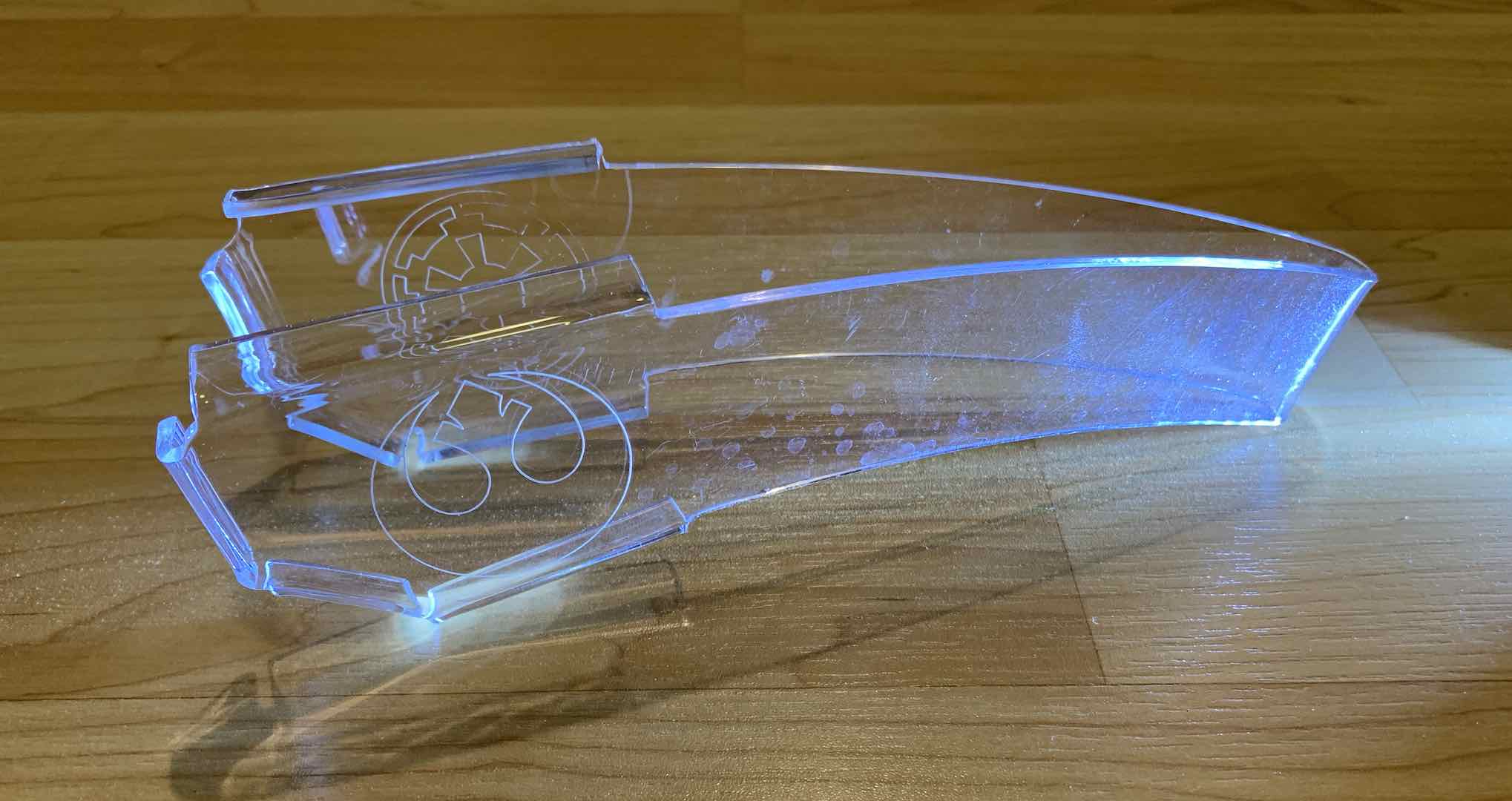

Manufacturing was pretty interesting because my design was different from everyone else’s. Not only did it have difficult to plot curves, but it also had engravings for the Star Wars symbols (Rebels and Empire). This necessitated the use of my CNC router to cut out the tongs. I used Fusion 360’s excellent CAM feature to make the tool paths. After a slightly stressful routing process, I sanded and polished every edge. Back at school, I used the heat strips provided to do all the bends.

Similarly to the cardboard prototypes, we also had to document how our salad tongs fulfilled every requirement in the design specifications. At the end of the day, I was left with experience in the engineering process and a nice set of salad tongs.

Comments